Earlier U.S. military vehicles, used from World War I through the Vietnam War, used a scheme of "olive drab", often with large white stars. Prototypes, early production M1 (105 mm gun) and M1-IP models switched to a flat forest green paint scheme. The large white insignia stars have also transitioned to much smaller black markings. Some units painted their M1s with the older Mobility Equipment Research and Design Command (MERDC) 4-color paint scheme but the turn-in requirements for these tanks required repainting them to overall forest green. Therefore, even though a large number of the base model M1s were camouflaged in the field, few or none exist today.

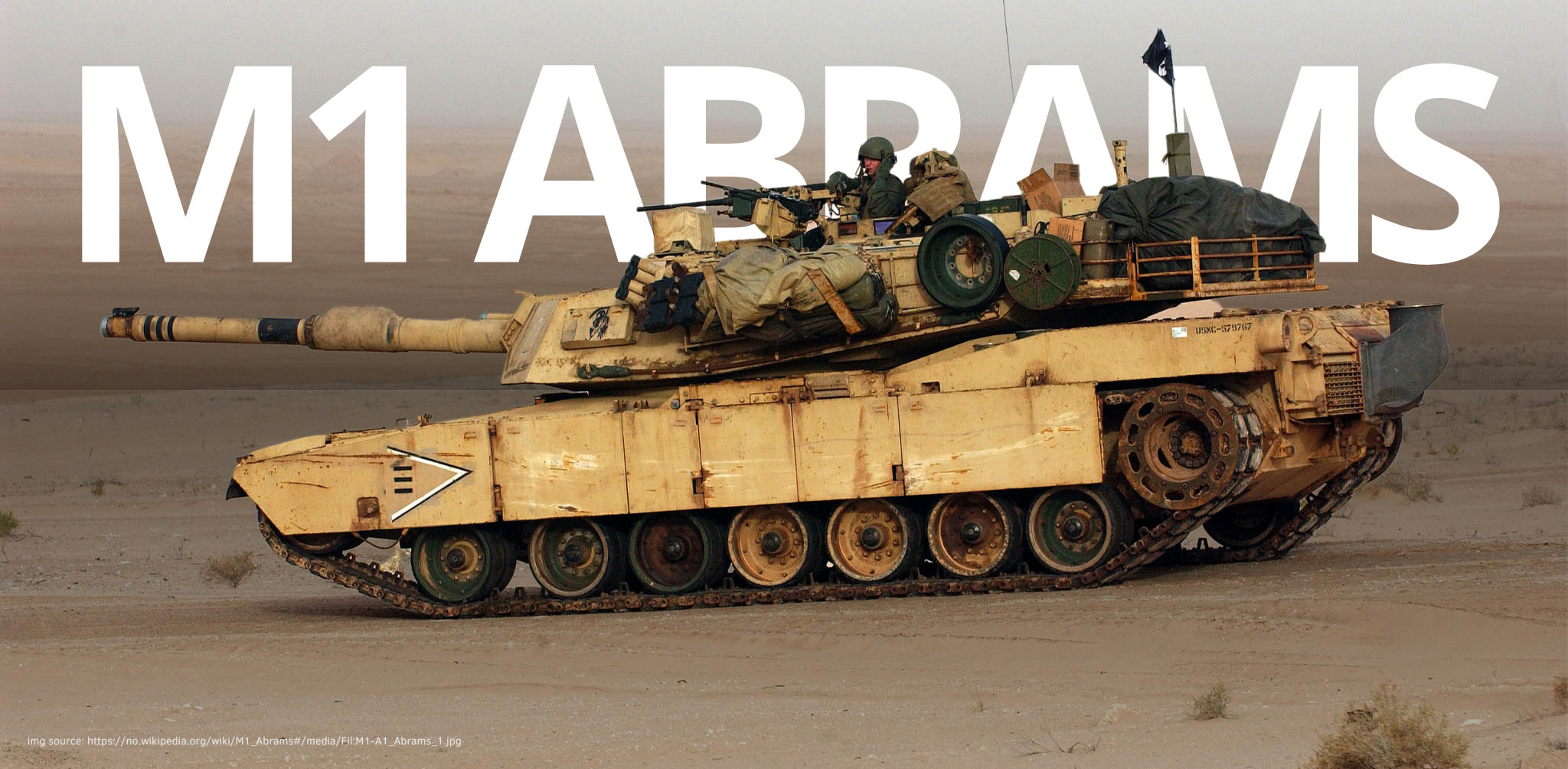

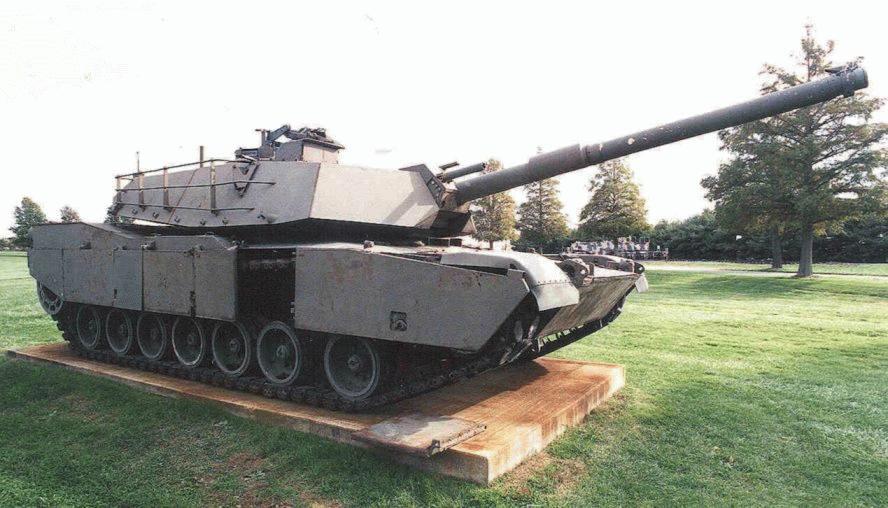

M1A1s came from the factory with the NATO three color camouflage Black/Med-Green/Dark-Brown Chemical Agent Resistant Coating (CARC) paint jobs.[citation needed] Today, M1A1s are given the NATO three color paint job during rebuilds. M1s and M1A1s deployed to Operation Desert Storm were hastily painted desert tan. Some, but not all, of these tanks were re-painted to their "authorized" paint scheme. M1A2s built for Middle Eastern countries were painted in desert tan. Replacement parts (roadwheels, armor skirt panels, drive sprockets, etc.) are painted olive green, which can sometimes lead to vehicles with a patchwork of green and desert tan parts.

Australian M1A1s were desert tan when delivered but have undergone a transition to the Australian Army vehicle standard 'Disruptive Pattern Camouflage'; a scheme that consists of black, olive drab, and brown.

The U.S. Army can equip its Abrams tanks with the Saab Barracuda camouflage system, which provides concealment against visual, infrared, thermal infrared, and broad-band radar detection.

The turret is fitted with two six-barreled M250 smoke grenade launchers (USMC M1A1s used an eight-barreled version), with one on each side. When deployed, the grenades airburst, creating a thick smoke that blocks both visual and thermal imaging. The engine is also equipped with a smoke generator that is triggered by the driver. When activated, fuel is sprayed into the hot turbine exhaust, creating the thick smoke. Due to a risk of fires however, this system is sometimes disabled.

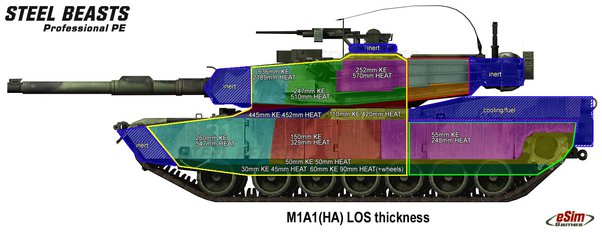

In July 1973, representatives from Chrysler and General Motors traveled to the United Kingdom, and were escorted by personnel from the Ballistic Research Laboratory and XM1 Project Manager Major General Robert J. Baer to witness the progress of British developed Chobham armor. They observed the manufacturing processes required for the production of Chobham armor, which was an arrangement of metal plates, ceramic blocks and open space; and saw a proposed design for a new British vehicle utilizing it.

HEAT and sabot rounds enter the beginning layers of armor but are unable to penetrate the crew compartment. Ceramics have the ability to absorb a great deal of heat, and can blunt physical blows by cracking and deflecting the force. The remaining hot gasses and metal shrapnel spread out or settle in empty air pockets. Both contractors reevaluated their proposed armor configurations based upon the newly obtained data.

This led to major changes in the General Motors XM1, the most prominent of which is the turret front changing from vertical to sloped armor. The Chrysler XM1 on the other hand retained its basic shape although a number of changes were made. The Ballistic Research Laboratory had to develop new armor combinations in order to accommodate the changes made by the contractors.

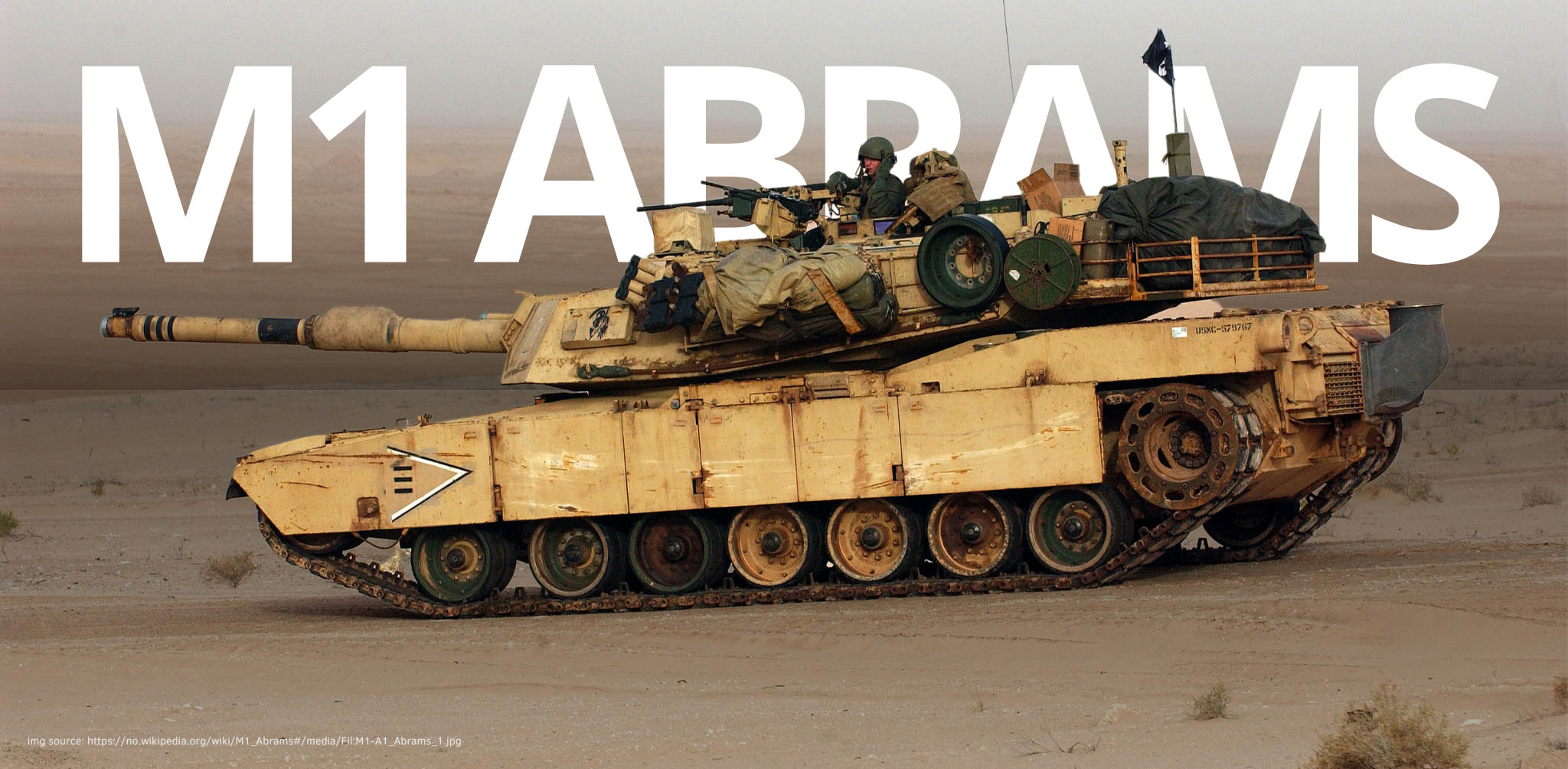

Similar to most other main battle tanks, the M1 Abrams feature composite armor only on the frontal aspect of the hull. However, the Abrams' turret features composite armoring across both the front and the sides. In addition, the side skirts of the frontal half of the hull are also made of composite, providing superior ballistic protection against chemical energy munitions such as HEAT rounds. The composition of the Abrams' composite armor consists of sandwiched plates of non-explosive reactive armor (NERA) between conventional steel plates. The NERA plates feature elasticity, allowing them to flex and distort upon perforation, disrupting the penetrating jets of shaped charges and providing more material and space for a kinetic round to pass through, thus providing increased protection compared to conventional steel armor of similar weight.[citation needed] For the M1 Abrams base model, Steven Zaloga estimates the frontal armor at 350 mm vs APFSDS and 700 mm vs HEAT warhead in the book, M1 Abrams Main Battle Tank 1982 1992 (1993). In M1 Abrams vs T-72 Ural (2009), he uses Soviet estimates of 470 mm (19 in) vs APFSDS and 650 mm (26 in) vs HEAT for the base model Abrams. He also gives the Soviet estimates for the M1A1, 600 mm (24 in) vs APFSDS, and 700 mm (28 in) vs HEAT.

Armor protection was improved by implementing a new special armor incorporating depleted uranium and other undisclosed materials and layouts.This was introduced into the M1A1 production starting October 1988. This new armor increased effective armor particularly against kinetic energy rounds but at the expense of adding considerable weight to the tank, as depleted uranium is 1.7 times denser than lead.

The first M1A1 tanks to receive this upgrade were tanks stationed in Germany. US-based tank battalions participating in Operation Desert Storm received an emergency program to upgrade their tanks with depleted uranium armor immediately before the onset of the campaign. M1A2 tanks uniformly incorporate depleted uranium armor, and all M1A1 tanks in active service have been upgraded to this standard as well. This variant was designated as the M1A1HA (HA for Heavy Armor).

The M1A1 AIM, M1A2 SEP and all subsequent Abrams models feature depleted uranium in both the hull and turret armor. Each Abrams variant after the M1A1 have been equipped with depleted uranium armor of different generations. The M1A1HA uses first generation armor, while the M1A2 and M1A1HC use second generation depleted uranium. The M1A2 SEP variants have been equipped with third generation depleted uranium armor combined with a graphite coating. The M1A2C also features increased physical line-of-sight turret armor.

For the M1A1HA, Zaloga gives a frontal armor estimate of 600 mm (24 in) vs APFSDS and 1,300 mm (51 in) vs HEAT in M1 Abrams Main Battle Tank 1982–1992, nearly double the original protection of the Abrams. In M1 Abrams vs T-72 Ural, he uses different estimates of 600 mm (24 in) vs APFSDS and 700 mm (28 in) vs HEAT for the front hull and 800 mm (31 in) vs APFSDS and 1,300 mm (51 in) vs HEAT for the front of the turret. The protection of M1A2 SEP is a frontal turret armor estimate of 940–960 mm (37–38 in) vs APFSDS and 1,320–1,6201,320–1,620 mm (52–64 in) vs HEAT, glacis estimate of 560–590 mm (22–23 in) vs APFSDS and 510–1,050 mm (20–41 in) vs HEAT, and lower front hull estimate of 580–650 mm (23–26 in) vs APFSDS and 800–970 mm (31–38 in) vs HEAT. The M1A2 SEPV3 increased the LOS thickness of the turret and hull front armor; total armor protection from this increase is not known.

In 1998, a program was begun to incorporate improved turret side armor into the M1A2. This was intended to offer better protection against rocket-propelled grenades that were more modern than the baseline RPG-7. These kits were installed on about 325 older M1A2 tanks in 2001–2009 and were also included in upgraded tanks.

The Abrams may also be fitted with explosive reactive armor over the track skirts if needed (such as the Tank Urban Survival Kit) and slat armor over the rear of the tank and rear fuel cells to protect against ATGMs. Protection against spalling is provided by a kevlar liner.

The tank has a halon firefighting system to automatically extinguish fires in the crew compartment. The engine compartment has a firefighting system that is engaged by pulling a T-handle located on the left side of the hull. The Halon gas can be dangerous to the crew. However, the toxicity of Halon 1301 gas at 7% concentration is much lower than the combustion products produced by fire in the crew compartment, and CO2 dump would be lethal to the crew.

The crew compartment also contains small hand-held fire extinguishers. Fuel and ammunition are stored in armored compartments with blowout panels intended to protect the crew from the risk of the tank's own ammunition cooking off (exploding) if the tank is damaged. The main gun's ammunition is stored in the rear section of the turret, with blast doors that open under power by sliding sideways only to remove a round for firing, then automatically close. Doctrine mandates that the ammunition door must be closed before arming the main gun.

The Tank Urban Survival Kit (TUSK) is a series of improvements to the M1 Abrams intended to improve fighting ability in urban environments. Historically, urban and other close battlefields have been poor places for tanks to fight. A tank's front armor is much stronger than that on the sides, top, or rear. In an urban environment, attacks can come from any direction, and attackers can get close enough to reliably hit weak points in the tank's armor or gain sufficient elevation to hit the top armor.

Armor upgrades include reactive armor on the sides of the tank and slat armor (similar to that on the Stryker) on the rear to protect against rocket-propelled grenades and other shaped charge warheads. A Transparent Armor Gun Shield and a thermal sight system are added to the loader's top-mounted M240B 7.62 mm machine gun, and a Kongsberg Gruppen Remote Weapon Turret carrying a 12.7 mm (.50 in) caliber machine gun (again similar to that used on the Stryker) is in place of the tank commander's original 12.7 mm (.50 in) caliber machine gun mount, wherein the commander had to expose himself to fire the weapon manually. An exterior telephone allows supporting infantry to communicate with the tank commander.

The TUSK system is a field-installable kit that allows tanks to be upgraded without needing to be recalled to a maintenance depot. While the reactive armor may not be needed in most situations, like those present in maneuver warfare, items like the rear slat armor, loader's gun shield, infantry phone (which saw use on Marine Corps M1A1s as early as 2003), and Kongsberg Remote Weapons Station for the 12.7 mm (.50 in) caliber machine gun will eventually be added to the entire M1A2 fleet.

In August 2006, General Dynamics Land Systems received a U.S. Army order for 505 Tank Urban Survivability Kits (TUSK) for Abrams main battle tanks supporting operations in Iraq, under a US$45 million contract. Deliveries were expected to be completed by April 2009. Under a separate order, the U.S. Army awarded General Dynamics Armament and Technical Products (GDATP) US$30 million to produce reactive armor kits to equip M1A2s. The reactive tiles for the M1 will be locally produced at GDATP's Burlington Technology Center.

Tiles will be produced at the company's reactive armor facility in Stone County Operations, McHenry, Mississippi. In December 2006, the U.S. Army added Counter Improvised Explosive Device enhancements to the M1A1 and M1A2 TUSK, awarding GDLS $11.3 million contract, part of the $59 million package mentioned above. In December, GDLS also received an order, amounting to around 40% of a US$48 million order, for loader's thermal weapon sights being part of the TUSK system improvements for the M1A1 and M1A2 Abrams Tanks.

In addition to the armor, some USMC Abrams tanks were equipped with a Softkill Active protection system, the AN/VLQ-6 Missile Countermeasure Device (MCD) that can impede the function of guidance systems of some semi-active control line-of-sight (SACLOS) wire- and radio guided anti-tank missiles (such as the Russian 9K114 Shturm) and infrared homing missiles. The MCD works by emitting a massive, condensed infrared signal to confuse the infrared homing seeker of an anti-tank guided missile (ATGM).

However, the drawback to the system is that the ATGM is not destroyed, it is merely directed away from its intended target, leaving the missile to detonate elsewhere. This device is mounted on the turret roof in front of the loader's hatch, and can lead some people to mistake Abrams tanks fitted with these devices for the M1A2 version, since the Commander's Independent Thermal Viewer on the latter is mounted in the same place, though the MCD is box-shaped and fixed in place as opposed to cylindrical and rotating like the CITV.

In 2016, the U.S. Army and Marine Corps began testing out the Israeli Trophy active protection system to protect their Abrams tanks from modern RPG and ATGM threats by either jamming (with ATGMs) or firing small rounds to deflect incoming projectiles. The Army planned to field a brigade of over 80 tanks equipped with Trophy to Europe in 2020. It is planned for up to 261 Abrams to be upgraded with the system, enough for four brigades. In June 2018, the Army awarded Leonardo DRS, U.S. partner to Trophy's designer Rafael, a $193 million contract to deliver the system in support of M1 Abrams "immediate operational requirements". U.S. Army M1A2 SEP V2 Abrams tanks deployed to Germany in July 2020 fitted with Trophy systems.[citation needed] Deliveries to equip four tank brigades were completed in January 2021.

The main armament of the original model M1 and M1IP was the M68A1 105 mm rifled tank gun firing a variety of APFSDS, HEAT, high explosive, white phosphorus rounds and an anti-personnel (multiple flechette) round. This gun used a license-made tube of the British Royal Ordnance L7 gun together with the vertical sliding breech block and other parts of the U.S. T254E2 prototype gun. However, a longer ranged weapon was always envisaged, with lethality beyond 1.9-mile (3 km) to combat newer armor technologies. To attain that lethality, the projectile diameter needed to be increased. The tank was able to carry 55 105 mm rounds, with 44 stored in the turret blow-out compartment and the rest in hull stowage.

The main armament of the M1A1 and M1A2 is the M256 120 mm smoothbore gun, designed by Rheinmetall AG of Germany, manufactured under license in the U.S. by Watervliet Arsenal, New York. The M256 is an improved variant of the Rheinmetall 120 mm L/44 gun carried on the German Leopard 2 on all variants up to the Leopard 2A5, the difference being in thickness and chamber pressure. Leopard 2A6 replaced the L/44 barrel with a longer L/55. Due to the increased caliber, only 40 or 42 rounds are able to be stored depending on if the tank is an A1 or A2 model.

Elevation: −9 to +20 degree

The M256 fires a variety of rounds. The primary APFSDS round of the Abrams is the depleted uranium M829 round, of which four variants have been designed. M829A1, known as the "Silver Bullet", saw widespread service in the Gulf War, where it proved itself against Iraqi armor such as the T-72. The M829A2 APFSDS round was developed specifically as an immediate solution to address the improved protection of a Russian T-72, T-80U or T-90 main battle tank equipped with Kontakt-5 explosive reactive armor (ERA).

Later, the M829A3 round was introduced to improve its effectiveness against next generation ERA equipped tanks, through usage of a multi-material penetrator and increased penetrator diameter that can resist the shear effect of K-5 type ERA.[citation needed] Development of the M829 series is continuing with the M829A4 currently entering production, featuring advanced technology such as data-link capability.

The Abrams also fires HEAT warhead shaped charge rounds such as the M830, the latest version of which (M830A1) incorporates a sophisticated multi-mode electronic sensing fuse and more fragmentation that allows it to be used effectively against armored vehicles, personnel, and low-flying aircraft. The Abrams uses a manual loader, who also provides additional support for maintenance, observation post/listening post (OP/LP) operations, and other tasks.

The new M1028 120 mm anti-personnel canister cartridge was brought into service early for use in the aftermath of the 2003 invasion of Iraq. It contains 1,098 3⁄8-inch (9.5 mm) tungsten balls that spread from the muzzle to produce a shotgun effect lethal out to 600 meters (2,000 ft). The tungsten balls can be used to clear enemy dismounts, break up hasty ambush sites in urban areas, clear defiles, stop infantry attacks and counter-attacks and support friendly infantry assaults by providing covering fire. The canister round is also a highly effective breaching round and can level cinder block walls and knock man-sized holes in reinforced concrete walls for infantry raids at distances up to 75 meters (246 ft).

Also in use is the M908 obstacle-reduction round. It is designed to destroy obstacles and barriers. The round is a modified M830A1 with the front fuse replaced by a steel nose to penetrate into the obstacle before detonation.

The U.S. Army Research Laboratory (ARL) conducted a thermal analysis of the M256 from 2002 to 2003 to evaluate the potential of using a hybrid barrel system that would allow for multiple weapon systems such as the XM1111 Mid-Range munition, airburst rounds, or XM1147. The test concluded that mesh density (number of elements per unit area) impacts accuracy of the M256 and specific densities would be needed for each weapon system.

In 2013, the Army was developing a new round to replace the M830/M830A1, M1028, and M908. Called the Advanced Multi-Purpose (AMP) round, it will have point detonation, delay, and airburst modes through an ammunition data-link and a multi-mode, programmable fuse in a single munition. Having one round that does the job of four would simplify logistics and be able to be used on a variety of targets. The AMP is to be effective against bunkers, infantry, light armor, and obstacles out to 500 m (1,600 ft), and will be able to breach reinforced concrete walls and defeat ATGM teams from 500 to 2,000 m (1,600 to 6,600 ft). Orbital ATK was awarded a contract to begin the first phase of development for the AMP XM1147 High-Explosive Multi-Purpose with Tracer cartridge in October 2015.

In addition to these, the XM1111 (Mid-Range-Munition Chemical Energy) was also in development. The XM1111 was a guided munition using a dual-mode seeker that combined imaging-infrared and semi-active laser guidance. The MRM-CE was selected over the competing MRM-KE, which used a rocket-assisted kinetic energy penetrator. The CE variant was chosen due to its better effects against secondary targets, providing a more versatile weapon. The Army hoped to achieve IOC with the XM1111 by 2013. However, the Mid-Range Munition was canceled in 2009 along with Future Combat Systems.

The Abrams tank has three machine guns, with an optional fourth:

The Abrams is equipped with a ballistic fire-control computer that uses user and system-supplied data from a variety of sources to compute, display, and incorporate the three components of a ballistic solution—lead angle, ammunition type, and range to the target—to accurately fire the main gun. These three components are determined using a laser rangefinder, crosswind sensor, a pendulum static cant sensor, data concerning performance and flight characteristics of each specific type of round, tank-specific boresight alignment data, ammunition temperature, air temperature, barometric pressure, a muzzle reference system (MRS) that determines and compensates for barrel drop at the muzzle due to gravitational pull and barrel heating due to firing or sunlight, and target speed determined by tracking rate tachometers in the Gunner's or Commander's Controls Handles.

All of these factors are computed into a ballistic solution and updated 30 times per second. The updated solution is displayed in the Gunner's or Tank Commander's field of view in the form of a reticle in both day and Thermal modes. The ballistic computer manipulates the turret and a complex arrangement of mirrors so that all one has to do is keep the reticle on the target and fire to achieve a hit. Proper lead and gun tube elevation are applied to the turret by the computer, greatly simplifying the job of the gunner.

The fire-control system uses this data to compute a firing solution for the gunner. The ballistic solution generated ensures a hit percentage greater than 95 percent at nominal ranges.[citation needed] Either the commander or gunner can fire the main gun. Additionally, the Commander's Independent Thermal Viewer (CITV) on the M1A2 can be used to locate targets and pass them on for the gunner to engage while the commander scans for new targets.

If the primary sight system malfunctions or is damaged, the main and coaxial weapons can be manually aimed using a telescopic scope boresighted to the main gun known as the Gunner's Auxiliary Sight (GAS). The GAS has two interchangeable reticles; one for HEAT and multi-purpose anti-tank (MPAT) ammunition and one for APFSDS and Smart Target-Activated Fire and Forget (STAFF) ammunition. Turret traverse and main gun elevation can be performed with manual handles and cranks if the fire control or hydraulic systems fail.

The commander's M2HB .50 caliber machine gun on the M1 and M1A1 is aimed by a 3× magnification sight incorporated into the Commander's Weapon Station (CWS), while the M1A2 uses the machine gun's own iron sights, or a remote aiming system such as the Common Remotely Operated Weapon Station (CROWS) system when used as part of the Tank Urban Survival Kit. The loader's M240 machine gun is aimed either with the built-in iron sights or with a thermal scope mounted on the machine gun.

In late 2017, the 400 USMC M1A1 Abrams were to be upgraded with better and longer-range sights on the Abrams Integrated Display and Targeting System (AIDATS) replacing the black-and-white camera view with a color sight and day/night thermal sight, simplified handling with a single set of controls, and a slew to cue button that repositions the turret with one command. Preliminary testing showed the upgrades reduced target engagement time from six seconds to three by allowing the commander and gunner to work more closely and collaborate better on target acquisition.

The M1 Abrams's powertrain consists of an AGT1500 multifuel gas turbine (originally made by Lycoming, now Honeywell) capable of 1,500 shaft horsepower (1,100 kW) at 30,000 rpm and 395 lb⋅ft (536 N⋅m) at 10,000 rpm and a six-speed (four forward, two reverse) Allison X-1100-3B Hydro-Kinetic automatic transmission. This gives it a governed top speed of 45 mph (72 km/h) on paved roads, and 30 mph (48 km/h) cross-country. With the engine governor removed, speeds of around 60 mph (97 km/h) are possible on an improved surface. However, damage to the drivetrain (especially to the tracks) and an increased risk of injuries to the crew can occur at speeds above 45 mph (72 km/h).

The tank was built around this engine and it is multifuel-capable, including diesel, gasoline, marine diesel and jet fuel (such as JP-4 or JP-8). In the AGT1500, jet fuel has poorer fuel economy and operating range compared to diesel. By 1989, the Army was transitioning solely to JP-8 for the M1 Abrams, part of a plan to reduce the service's logistics burden by using a single fuel for aviation and ground vehicles. However, as of 2023, the U.S. Army frequently refuels the Abrams with diesel, which is also used by the Bradley Fighting Vehicle. The Australian M1A1 AIM SA burns diesel fuel, since the use of JP-8 is less common in the Australian Army.

The gas turbine propulsion system has proven quite reliable in practice and combat, but its high fuel consumption is a serious logistic problem. The engine burns more than 1.67 US gallons per mile (392 Liters/100 km) or (60 US gallons (230 L) per hour) when traveling cross-country and 10 US gallons (38 L) per hour when idle.

The high-speed, high-temperature jet blast emitted from the rear of M1 Abrams tanks makes it hazardous for infantry to take cover or follow behind the tank in urban combat.[citation needed] The turbine is very quiet when compared to diesel engines of similar power output and produces sound significantly different from a contemporary diesel tank engine, reducing the audible distance of the sound, thus earning the Abrams the nickname "whispering death" during its first Reforger exercise.

The Army received proposals, including two diesel options, to provide the common engine for the XM2001 Crusader and Abrams. In 2000, the Army selected the gas turbine engine LV100-5 from Honeywell and subcontractor General Electric. The new LV100-5 engine was lighter and smaller (43% fewer parts) with rapid acceleration, quieter running, and no visible exhaust. It also featured a 33% reduction in fuel consumption (50% less when idle) and near drop-in replacement. The Common Engine Program was shelved when the Crusader program was canceled. Phase 2 of Army's PROSE (Partnership for Reduced O&S Costs, Engine) program, however, called for further development of the LV100-5 and replacement of the current AGT1500 engine.

From 1991 to 1994, the Army fitted 1,500 Abrams turrets with external Auxiliary Power Units (APU). APUs allow some the Abrams to run some functions without running on the engine. Some Abrams tanks that saw service during the Gulf War were fitted with such a device. Although the Army favored an under-armor APU, Congress instead funded a short-term modification to 336 M1A2 Abrams. These were installed in 1997. An under-armor APU located in the hull was chosen for the M1A2 SEP variant. When this proved unreliable, it was replaced with a battery-based Alternate APU starting in 2005..

Although the M1 tank is not designed to carry riders easily, provisions exist for the Abrams to transport troops in tank desant with the turret stabilization device switched off. A battle equipped infantry squad may ride on the rear of the tank, behind the turret. The soldiers can use ropes and equipment straps to provide handholds and snap links to secure themselves. If enemy contact is made the tank conceals itself,[clarification needed] allowing the infantry to dismount.

Strategic mobility is the ability of the tanks of an armed force to arrive in a timely, cost effective, and synchronized fashion. The Abrams can be carried by a C-5 Galaxy or a C-17 Globemaster III. The limited capacity (two combat-ready tanks in a C-5, one combat-ready tank in a C-17) caused serious logistical problems when deploying the tanks for the first Gulf War, though there was enough time for 1,848 tanks to be transported by ship.

The Marines transported their Marine Air-Ground Task Force Abrams tanks by combat ship. A Wasp-class Landing Helicopter Dock (LHD) typically carried a platoon of four to five tanks attached to the deployed Marine Expeditionary Unit, which were then amphibiously transported to shore by Landing Craft Air Cushion (LCAC) at one combat-ready tank per landing craft.

The Abrams is also transportable by truck, namely the Oshkosh M1070 and M1000 Heavy Equipment Transporter System (HETS) for the US Military. The HETS can operate on highways, secondary roads, and cross-country. It accommodates the four tank crew members. The Australian Army uses customised MAN trucks to transport its Abrams.

The first instance of the Abrams being airlifted directly into a battlefield occurred in October 1993. Following the Battle of Mogadishu, 18 M1 tanks were airlifted by C-5 aircraft to Somalia from Hunter Army Airfield, Georgia.

Preproduction test model. Eleven Full-Scale Engineering Development test bed vehicles were produced in 1977–78. These vehicles were also called Pilot Vehicles and numbered PV-1 through PV-11.

First production variant. Production began (at Chrysler) in 1979 and continued to 1985 (at General Dynamics) (3,273 built for the US). The first 110 tanks were low rate initial production (LRIP) models, still called XM1s, because they were built before the tank being type-classified as the M1.

Produced briefly in 1984 before the M1A1, contained upgrades and reconfigurations like new turret with thicker frontal armor, new turret with rear storage rack is referred as long turret instead of older short turret, armor upgraded from ~650mm line of sight thickness to ~880mm.

Production started in 1985 and continued to 1992, pressurized NBC system, rear bustle rack for improved stowage of supplies and crew belongings, redesigned blow-off panels and M256 120 mm smoothbore cannon (4,976 built for the U.S. Army, 221 for USMC, 59 M1A1 AIM SA sold to Australia).

Added first generation depleted uranium armor components. Some tanks were later upgraded with second generation depleted uranium armor components, and are unofficially designated M1A1HA+.

Added new second generation depleted uranium armor components, digital engine control and other small upgrades common between Army and Marine Corps tanks.

A digital upgrade for the M1A1HC, to keep up with M1A2 SEP, manufactured in quantity for only 2 battalions.

The tank is improved by adding Forward-Looking InfraRed (FLIR) and Far Target Locate sensors, a tank-infantry phone, communications gear, including FBCB2 and Blue Force Tracking to aid in crew situational awareness, and a thermal sight for the .50 caliber machine gun.

Upgrades similar to AIM v.1 tanks + new third generation depleted uranium armor components. Configuration for the Royal Moroccan Army, which is almost identical to the Australian variant, except exportable turret armor is installed by General Dynamics Land System to replace the DU armor.

Similar upgrade to AIM v.2 for USMC tanks.

M1A1s that have been visually modified to resemble Soviet-made tanks for use at the National Training Center, fitted with MILES gear and a Hoffman device.

An export variant ordered by the Iraqi Army.

.jpg)

Upgrade-only variant to all USMC General Dynamics M1A1 Abrams tanks to improve the tank commander's situational awareness with an upgraded thermal sight, color day camera, and a stationary color display.

Production began in 1992 and initial operating capability achieved in 1993. (77 built for the U.S. and more than 600 M1s upgraded to M1A2, 315 for Saudi Arabia, 1,005 for Egypt, 218 for Kuwait). The M1A2 offers the tank commander an independent thermal sight and ability to, in rapid sequence, shoot at two targets without the need to acquire each one sequentially, also second generation depleted uranium armor components.

Has increased power generation and distribution, better communications and networking, new Vehicle Health Management System and Line Replaceable Modules for improved maintenance, an Ammunition DataLink to use airburst rounds, improved counter-IED armor package, Next Generation Armor Package, and an APU under armor to run electronics while stationary instead of the engine, visually distinguishing the version by a small exhaust at the left rear. More passive ballistic protection added to the turret faces, along with new Explosive Reactive Armor mountings and Active Protection systems added to the turret sides. Prototypes began testing in 2015, and the first were delivered in October 2017. The first unit received them in July 2020.

Variant for the Romanian Army, currently under development. According to the chief of the General Directorate for Armaments, the Romanian Abrams variant will be a configuration of the M1A2 SEPv3.

Special configuration variant of the M1A2 SEPv3 reportedly being offered for sale to Taiwan as of March 2019 and approved by US State Department as of July 2019. Per DSCA statement, it is roughly equivalent to M1A2 SEPv3, except depleted uranium armor is replaced by FMS export armor. There is no mention of the Trophy APS system. The new-built tanks will be produced at Anniston Army Depot, Anniston, Alabama, and the Joint Systems Manufacturing Center, Lima, Ohio.

Added Common Remotely Operated Weapon Station low-profile as standard, color displays, improved interfaces, a new operating system, improved crew-compartment cooling, and new second generation thermal optics.

The Commander's Primary Sight, also known as the Commander's Independent Thermal Viewer, and Gunner's Primary Sight will be upgraded with third Gen FLIR, an improved laser rangefinder and color cameras. Additional improvements will include advanced meteorological sensors, laser warning/detection receivers, directional smoke grenade launchers and integration of the new XM1147 advanced multi-purpose sv 120mm tank round. The AN/VVR-4 laser warning receiver and ROSY rapid obscurant system have been trialed by the US Army for adoption on the Abrams tank and Bradley fighting vehicle. The M1A2 SEPv4 variant was officially canceled by the U.S. Army on 6 September 2023. The Army plans to develop a new variant of the Abrams, designated M1E3, to enter service in the 2030s.

Under development, unique variant for the Kuwaiti Army, slated to replace Kuwait's current M1A2 fleet.

On 6 September 2023, the U.S. army announced that it had canceled the planned M1A2 SEPv4 variant and would instead redirect resources into a new variant of the Abrams tank, named M1E3. The new variant will include modular open-systems architecture and is designed to be lighter and more survivable on the battlefield.

was a prototype built in 1983, featuring an unmanned turret with a 44-caliber 120mm M256 smoothbore gun, three crew members sitting side by side inside an armored capsule at the front of the hull and a suite of cameras and thermal viewers to preserve the crew's situational awareness. The main armament was linked to a mechanical autoloader and a 44-round vertical ammunition carousel inside the turret basket; this system could provide a sustained rate of fire of 10 rounds per minute and successfully completed over 40,000 round loading/unloading cycles without malfunctioning during testing. Due to the absence of a full-fledged manned turret and the lack of internal armor packages, the vehicle only weighed 45 tons. The program was cancelled after the end of the Cold War and its only prototype is now on display at the U.S. Armor & Cavalry Collection museum at Fort Moore, Georgia.

was a single M1A1 fitted with a heavily modified turret to trial the experimental XM291 ATAC (sometimes referred to as LW120) smoothbore gun, a more powerful replacement for the M256 capable of firing either single-piece 120mm or two-piece 140mm ammunition with only a barrel change. The 140mm rounds were too large (boasting twice the chamber volume of a M829 APFSDS and twice the muzzle energy) and heavy to be moved around by a human loader, mandating the installation of a XM91 mechanical cassette autoloader. The Thumper underwent testing in 1988 and in the 1990s at Aberdeen Proving Ground, where it demonstrated accuracy equal to a M1A1's but with significantly higher armor penetration capability.

Is fitted with new, second-generation gunner's thermal sight. Has upgraded third-generation depleted uranium armor components with graphite coating (240 new built, 300 M1A2s upgraded to M1A2 SEP for the US, also unknown numbers of upgraded basic M1s and M1IPs, also 400 oldest M1A1s upgraded to M1A2 SEP).

was a pair of highly modified prototypes conceived under the auspices of the AVAS program to test several promising technologies. Two vehicles were built in 1993 and 1994: the first one, dubbed Phase I, paired a spare M1 hull with a modified turret fitted with a 48-caliber 140mm Watervliet Arsenal smoothbore cannon and a Benét Labs XM91 mechanical autoloader inside the bustle; the second vehicle, codenamed Phase II, used the same turret as basis, but mated it to a brand new M1 hull altered to contain a more compact AIPS diesel engine and two vertically-stacked, horizontal carousels between the turret basket and the powerpack compartment. Phase II also trialed new single-shoe XT166 tracks, an in-arm hydropneumatic suspension and the Multi-Sensor Target Acquisition System with its low-power, millimetric wave radar. Both vehicles were tested extensively at Aberdeen Proving Ground.

Saudi Arabian variant upgrade of the M1A2 based on M1A2 SEP, with some features, such as depleted uranium armor, believed to be missing and replaced by special armor. (442 M1A2s upgraded to M1A2S).

The AbramsX features a lightweight Watervliet Arsenal XM360 smoothbore gun with pepperpot muzzle brake, an autoloader which reduces the crew to three, an unmanned turret, a hybrid diesel-electric Cummins ACE power pack that gives 50% more fuel efficiency, a 30 mm XM914 chain gun in a remote weapon station, Trophy active protection systems with three launchers, an augmented reality suite that would increase the crews' situational awareness thanks to cameras and sensors mounted around the tank's exterior, a silent mode when running on electric power, the ability to be updated more easily than existing tanks and use loitering munitions such as the AeroVironment Switchblade as well as surveillance drones, and reduced weight for improved mobility. In October 2022, GDLS released a video showing the Technology Demonstrator and various technology tests.

Proposed air defense variant of the Abrams equipped with dual 35 mm Bushmaster III autocannons, 12 ADATS missiles and advanced electro-optical and radar targeting systems derived from the ADATS. It was supposed to be capable of both air defense and anti-tank purposes with the ADATS MIM-146 missiles which was a dual purpose ATGM/SAM. The proposal never saw consideration and was never developed further.

A remote controlled mine clearing vehicle with turret removed, mine rollers on front, and the Standardized Teleoperation System.

GDLS produced these under contract for the U.S. Army with testing beginning in 1996. The 26 meters (85 ft) bridge was produced by Krauss-Maffei Wegmann. The chassis is an Abrams converted to M1A2 standard. Forty-three units were produced when production wrapped up in 2003.

The vehicle was visually modified to with a mock M256 gun to appear like an ordinary Abrams MBT, but featured communications equipment and workstations for battle commanders. United Defense LP constructed a prototype which the Army tested at Fort Hood in 1997.

The National Training Center possesses 28 visually modified M1A1s resembling T-80s.

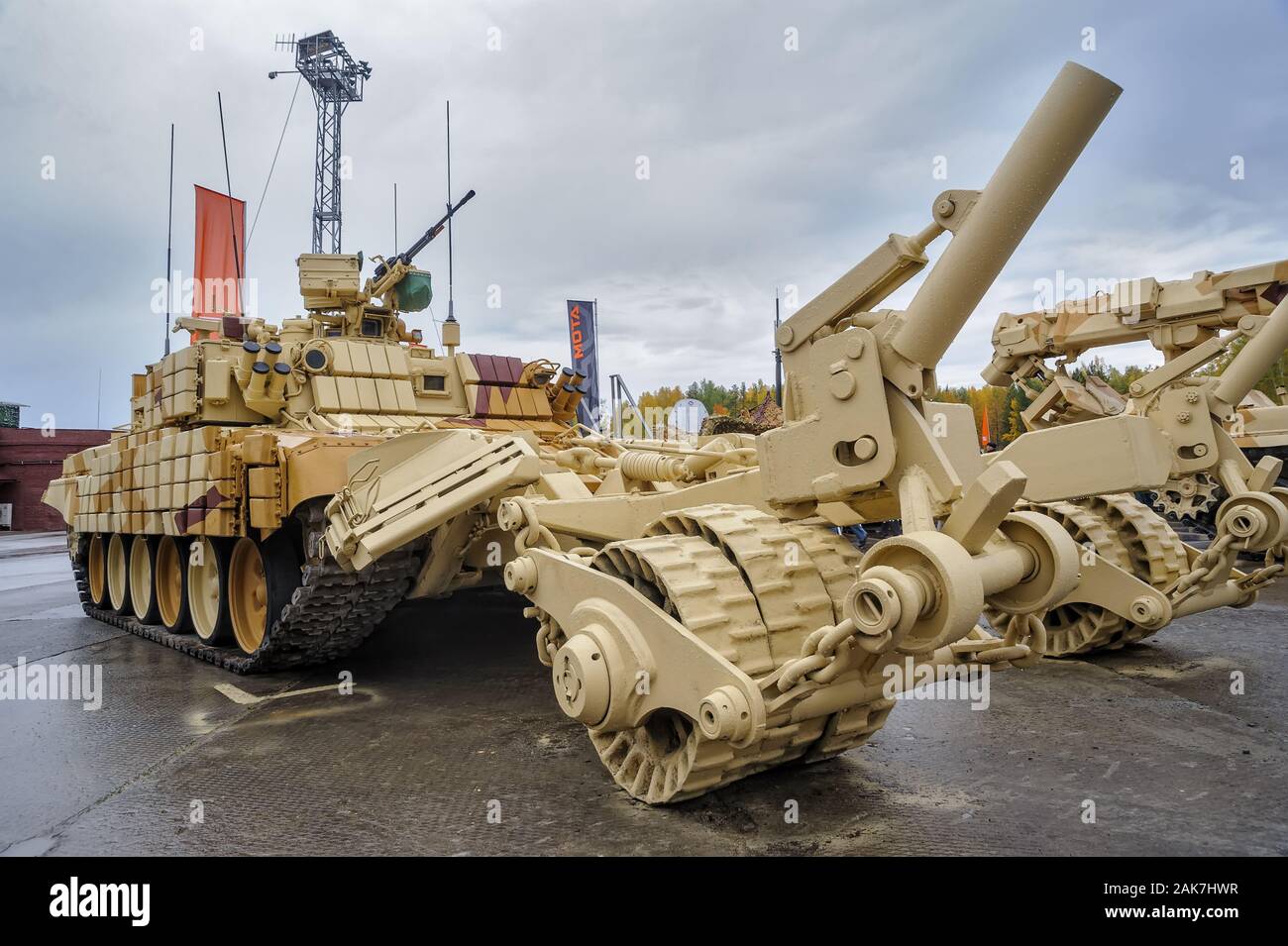

In 1997 TACOM awarded United Defense a $129 million contract to construct this vehicle based on the Abrams chassis. This was capable of clearing minefields and demolishing obstacles with its dozer blade and telescopic power-driven arm.

Bridgelayer combining a heavy "scissor" bridge with the M1 Abrams chassis. Expected to reach low-rate initial production in 2019 to replace the M60 AVLB and M104 Wolverine.

Assault variant for the USMC. Based upon the M1A1 Abrams chassis. Reactive armor has been fitted to the vehicle providing additional protection against HEAT warhead-based weapons.

this was a prototype designed by General Dynamics. The prototype was evaluated against the M88A1E1 later that year. The Army selected the M88A1E1 regardless, which went into production as the M88A2 Hercules.

An early example consisted of two mine plows and a chain with a weight running between them. The Mine Clearing Blade System (MCBS):It is capable of clearing mines up to 6 feet in front of the tank's path.

The Tank Mounted Mine Clearing Roller comprises two roller banks of five discs each and a chain with a weight running between the rollers. Self Protection Combat Roller targets pressure activated explosive devices. The system comprises two 4-wheel roller gangs.

The SCD is employed to clear surface laid mines and IEDs from roads, trails and rough terrain. There are two versions of the SCD; a V-blade optimised for clearing routes and a straight angle-blade which is optimised for clearing staging and assembly areas.

The VEMSID causes detonation of magnetic influence mines. The system comprises four emitter coils, two associated power boxes and an MSD Control Unit (MSDCU).

The U.S. Army tested this attachment in 1982. This was unsuccessful in part because it resulted in transmission overheating, and was never used.